Any Shape, Any Die, Any Press

Manufacturing

De Mari has a long-standing commitment to product quality.

Manufacturing Facility Photos

Capabilities

De Mari provides complete manufacturing of extrusion dies and equipment.

Development of new shapes from concept, to testing, to production

Replication of existing pasta products

Manufacturing of 'inserts' for existing 'die holders'

New Bronze Aluminum die holders, with interchangeable inserts for all pasta presses

Technical support and troubleshooting for all aspects of pasta extrusion

Length control for 'long goods' and 'short goods' products

Compensated 'inserts' and bushings to correct curving and product length control

Materials Used

De Mari believes in utilizing materials that will not only give the finest end result to the customer, but also provide reliability and long life. We will manufacture dies and inserts to any customer requirements, as well as provide customers with suggested materials to enhance all areas of extrusion.

Materials used to manufacture ‘dies’ and ‘inserts’ include but are not limited to:

Bronze aluminum

Stainless steel

Brass

Ultra-high-molecular-weight polyethylene (UHMW)

DELRIN

Virgin Teflon

TFM 1700 (High Density Teflon)

Nickel plating

Hard chromium plating

Quality Control

For Over a Decade and a Half, De Mari has relied on the quality of its products to fuel its growth.

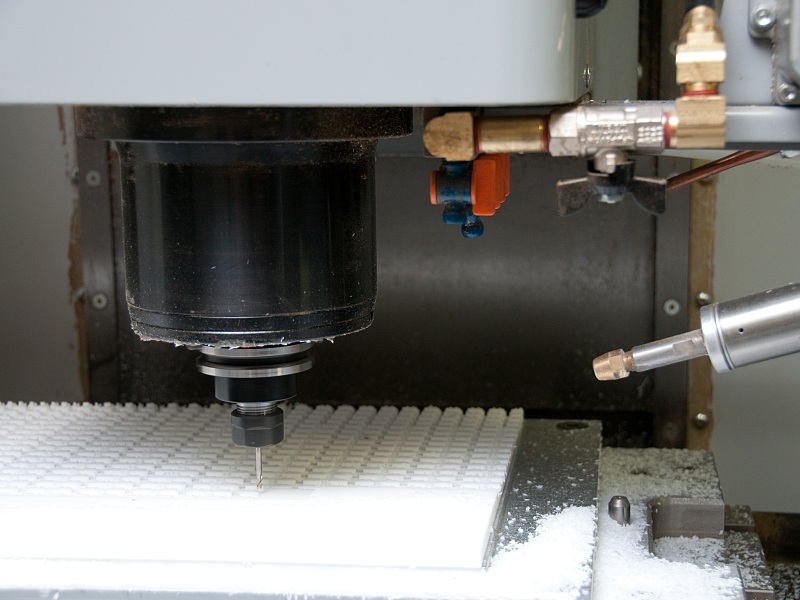

Medical Grade Tooling is exclusively used to guarantee the utmost precision, quality and repeatability.

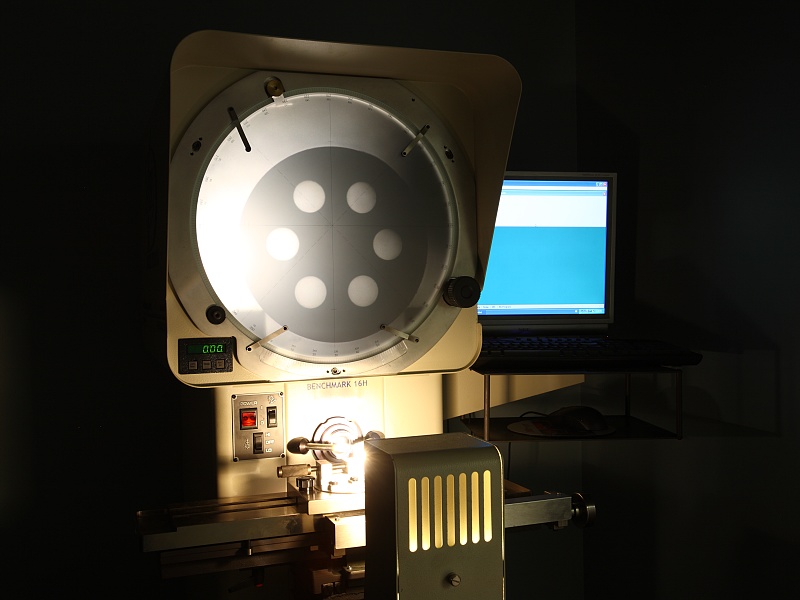

Optical Comparator, with reverse engineering software, ensures parts are within tolerances and specifications.

An in-house 100 kg per hour Lab Press is used to test new designs as well as design modifications.

3-axis Vertical Machining Centers with multiple pallets ensure accuracies and repeatability of up to 0.00001".

Copyright © 2025, Terms

De Mari Pasta Dies USA, Inc.

48 Chuck Drive, Dracut, MA 01826

P: 978.454.4099, F: 978.454.1501

Hablamos Español, Parliamo Italiano, Falamos Português